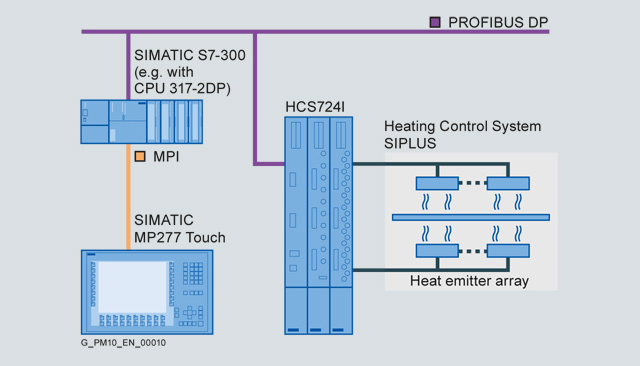

The HCS724I heating control system is used, for example, to control heat emitter arrays in

and other applications.

HCS724I heater control | |

Climatic ambient conditions | |

Operating temperature | |

| 0 ... 55 °C |

| 95 % |

| ≤ 10 K/h |

Storage temperature | |

| -40 ... +70 °C |

| 95 % |

| ≤ 20 K/h |

Air pressure during operation | |

| 860 hPa (= 1 500 m above sea level) |

| 1 080 hPa |

Air pressure during storage | |

| 660 hPa (= 3 500 m above sea level) |

| 1 080 hPa |

Ventilation | Self ventilation or forced ventilation |

Mechanical ambient conditions | |

Vibration during operation (stationary use) | IEC 60068-2-6 Test FC (10 cycles per axis) |

| 0.075 m amplitude |

| 9.8 m/s2 (= 1 g constant acceleration) |

Vibration during transport/storage | IEC 60068-2-6 Test FC (10 cycles per axis) |

| 3.5 mm amplitude |

| 9.8 m/s2 (= 1 g constant acceleration) |

Shock during operation (stationary use) | IEC 60068‑2‑27 Test EA |

Shock during transport/storage | IEC 60068‑2‑29 Test EB |

Electromagnetic compatibility | |

Radio interference suppression (emitted interference) | Limit value class A in accordance with EN 55011 Group 1 |

Immunity to conducted interference (burst) | According to EN 61000-4-4 |

| 2 kV with switching network |

| 2 kV with clamp |

Immunity to conducted interference | According to EN 61000‑4‑6: 10 V (0.15 to 80 MHz) |

Interference immunity to static electricity (ESD) | Acc. to EN 61000-4-2 |

| 4 kV |

| 8 kV |

Immunity to high-frequency interference | EN 61000‑4‑3 |

Immunity to high-energy pulses (surge) | Acc. to EN 61000-4-5 |

Power supply lines | |

| 1 kV |

| 2 kV |

PROFIBUS cable | |

| 1 kV |

The main components of the SIPLUS HCS724I heater control system are:

The ZA724I central interface module and the LA724I/LA724I HP/LA724I SSR power output modules are installed in a metal enclosure and mounted on a plate in the control cabinet.

Customized, distributed solutions are also possible.

Application example with SIMOTION, SINAMICS, and SIPLUS HCS724I

Additional information can be found on the Internet at http://www.siemens.com/hcs.