With the verification license "Veri-Genius", devices of the SIMATIC MV440 family can be used for checking the marking quality of codes (verification) in addition to reading 1D barcodes and 2D matrix codes.

The license is supplied as a "Single License" on a USB flash drive and can be installed via the SIMATIC Automation License Manager (ALM) on any reader of the SIMATIC MV440 series. The license is executable on a SIMATIC MV440 as of firmware version 4.0.

Applications for verification span across almost all sectors. To maximize read rates in production and logistics and to make them predictable, it is essential to measure the marking quality.

The following sectors and applications are a particular focus for MV440 verification systems:

"Veri-Genius" can be used anywhere where environmental conditions permit the use of MV440 code readers - for details, see SIMATIC MV440. Standard ring lights and lenses are designed to achieve IP67 degree of protection by means of the protective barrel, and for glass-free use in the food and beverages industry. If light sources or lenses are used outside the protective barrel, they must be used in compliance with their specification.

Any host and HMI systems required must be selected sector-specifically and project-specifically. The range of application of the selected test method is defined in the specification of the test method and compliance is essential if universally valid results are to be obtained.

All SIMATIC MV440 stationary code readers are basic units under the terms of the license. The verification functionality is enabled by transferring the license key from the USB flash drive on which it is supplied to the MV440 code reader by means of SIMATIC License Manager.

Verification with MV440 verification systems is suitable for both inline and offline measurements. In both cases, the specification of the verification standard used must be observed to ensure a robust measurement result. This means, for example, that the lighting and alignment of the light source, camera and test object must be in accordance with the definitions of the respective standard.

If only one light source is used, the MV440 can control an external light source using the existing image-synchronized digital output, or the external light source can be operated continuously.

If more lighting directions are required, an external controller can be used to activated the desired lighting and to start each individual measurement by means of triggering. The result from the quality measurement or the relevant partial measurement is output directly by the MV440 after completion of the measurement. In the case of more than one measurement, it is the task of the external controller to combine the partial results into an overall result and to visualization this.

If the test method requires calibration, the calibration card included in the scope of supply can be used in most cases. In cases with extreme imaging requirements (e.g. with very small or very large codes), the task of calibration must be resolved application-specifically.

Verification of code quality is an additional function subject to a license that can be activated on any SIMATIC MV440 by installing the "Veri-Genius license". The functionality is available without a license in demo mode.

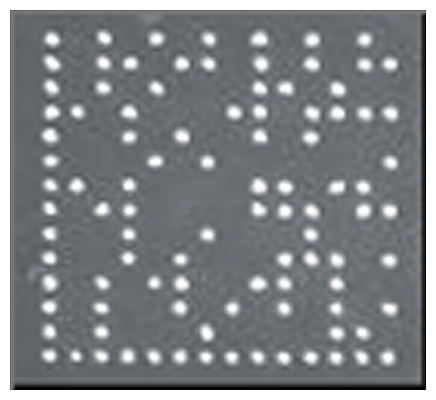

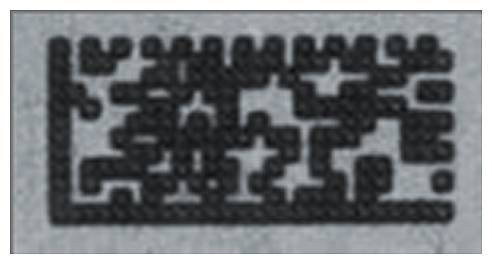

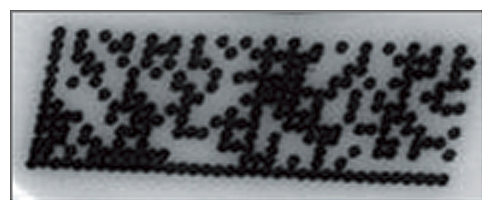

The following typical types of fault can be detected by measuring the marking quality - the following pictures show examples of correct code and faults in the marking quality:

Correct code

Incorrect or non-uniform cell size in the marking

Incorrect or non-uniform cell size in the marking

Incorrect or non-uniform cell position in the marking

Incorrect overall geometry of the marking

Damaged surface of the marking or part

Very little or non-uniform contrast in the marking

Very little or non-uniform contrast in the marking

The following measuring procedures/standards are available for the purposes of inspection:

The measurement result is output as an overall result in 5 stages, which are named using letters or numbers:

Overall result as a digit | Overall result as letters | Overall result as text |

|---|---|---|

4 | A | Top quality |

3 | B | Good quality |

2 | C | Satisfactory quality |

1 | D | Adequate quality |

E | (not used) | |

0 | Fault | Marking quality inadequate |

The components of a measurement result and calculation of the overall result are dependent on the test method used.

The overall result and the components of a measurement result can be output after a test, and are then available for further processing on an external system, e.g. for archiving or creating a test report.

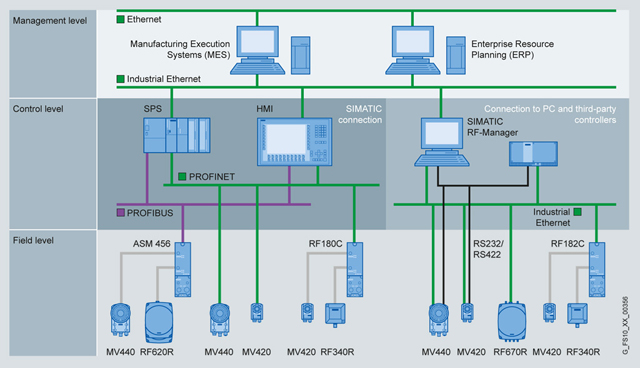

The MV440 verification systems can use all communication services that the basic units of the SIMATIC MV440 family offer:

Usable communication services | |

|---|---|

PROFINET IO (FB79) | Onboard MV440 PROFINET interface. |

PROFINET IO (FB45, PIB) | Via the MV440 ASM interface using the ASM module RF180C. |

PROFIBUS DP V0/1 (FB45, PIB) | Via the MV440 ASM interface using the ASM module ASM456. |

TCP/IP native | Onboard MV440 PROFINET interface. |

The most important types of interface in the automation environment are shown in the overview below. For further details, refer to the chapter SIMATIC MV440.

| Код | Заказной номер | Заказать |

|---|---|---|

| 66243 | 6GF3400-0SL02 | Заказать |