The MicroSAM is a miniaturized process gas chromatograph (GC) in an Ex d enclosure. Through consistent use of microsystem technology (silicon wafer technology), all analytical components are concentrated in the smallest possible area. The design particularly enables a distributed installation close to the process.

Analysis of exhaust gas in blast furnaces.

Analysis of mine gas for inert gases and hydrocarbons.

MicroSAM | |

Design, enclosure | |

Weight | 15 kg |

Degree of protection | IP65 (NEMA 4X) |

Mounting | |

Installation on | Post, pipe or wall |

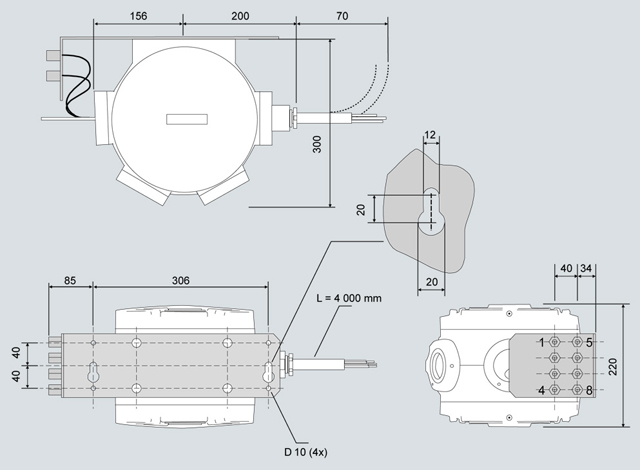

Distance from wall or next chromatograph | 300 mm (12") |

Distance from ceiling or floor | 200 mm (8") |

Explosion protection | ATEX II 2 G Ex d IIC T4 Gb DMT 03 ATEX E 069 X IEC Ex BVS 10.0004X CSA Class I, Div 1, Groups B, C, D T4 |

Support bracket | |

| 380 x 110 mm |

| 8 |

| 146 x 110 mm |

Electrical characteristics | |

Power supply | 24 V DC (18.5 ... 30.2 V) |

Power consumption | |

| 18 W |

| 60 W |

| IEC 61010 / DIN VDE 0411 |

EMC immunity | According to IEC 60801/DIN VDE 0843 |

| |

| 2 kV |

| 1 kV |

| 2 kV |

| |

| 1 kV |

| |

| 8 kV |

| |

| 10 V/m |

| According to CISPR 11 / EN 55011 / DIN VDE 0875 Limit class B |

| T2.5 A |

Gas inlet conditions | |

Permissible sample pressure | 10 … 50 kPa |

Sample flow | 20 … 100 ml/min |

Max. sample temperature | 120 °C |

Solid components | < 0.1 mm |

Climatic conditions | |

Permissible ambient temperature | - 20 ... 50 °C (depending on oven temperature) |

Permissible storage/transport temperature | - 30 ... 70 °C |

Permissible relative humidity | Max. 90% |

Sample and injection | |

Sample streams | 3 |

Calibration sample streams | 1 |

Phase | Gaseous |

Required filtration | Degree of separation 99.99 % for < 0.1 μm particles |

Material with which the sample comes into contact | Stainless steel, fused silica, polyimide |

Injection | "Valveless" live injection |

| With multifunctional diaphragm valve |

| 2 ... 50 µl |

| 165 °C |

Oven | |

Number/type | 1/isothermal |

Purging with N2 | Possible |

Dimensions (DxH) | 160 x 10 mm |

Heating capacity | 20 W |

Temperature range | 60 … 155 °C |

Temperature stability | ± 0.1 K (60 ... 155 °C) |

Temperature accuracy | ± 3 K (60 ... 155 °C) |

Retention time variations per 10 °C change in ambient temperature | Approx. 0.3% |

Heating-up period from 30 ... 100 °C | 10 minutes |

Columns and gases | |

Column type | Capillary columns 0.15 ... 0.25 mm/internal |

Separating column switching | Multidimensional chromatography with backflushing and cut in live system |

Multifunctional diaphragm valve | For injection and backflushing |

Gas connections | Swagelok 1/8" |

Pressure regulators | Max. 4 single-channel electronic pressure regulators |

Solenoid valves for control of diaphragm valve | 2 NC contacts, 2 NO contacts |

Carrier gas | H2, N2, He, Ar |

| > 99,999 % (5.0) |

| < 0.1 μm |

| Degree of separation 99.99% for < 0.1 μm particles |

| 10 ... 60 ml/min |

| 500 … 700 kPa |

Instrument air | Not required |

Detectors, calibration and performance data | |

Detector type | TCD, max. 8 sensors |

Ambient temperature | Negligible |

Vibrations | Negligible |

Cell volume | 0.02 μl |

Calibration | Manual or automatic, single-level or multi-level |

Smallest measuring range | 1 000 ppm (application-dependent) |

Linear range | Typically > 104 |

Cycle time | Typically 30 … 240 s |

Electrical inputs and outputs | |

Basic equipment | |

| 4, freely usable (expandable by NAU or I/O Extender, see communication in "General information") |

| 4, 3 freely usable (expandable by NAU or I/O Extender, see communication in "General information") |

Interfaces | |

| 1 x Ethernet 10BaseT / TCP/IP |

| 1 x RS 485 or RS 232 / Modbus RTU, OPC (ODPC) over Ethernet |

Electronics | |

Communication and analytical controller (CAC) | |

| Intel 586 architecture |

| 128 MB |

| 64 MB |

| Windows CE 5.0 |

| Preinstalled. Modifications or upgrades for operation PC downloadable via network or locally |

Realtime signal processor (RSP) | |

| Motorola 68376, 20 MHz |

| 1 MB |

| 1 MB |

| Forth |

| Preinstalled. Modifications or upgrades downloadable via internal service interface |

Controller | |

| 3 |

| 1 |

|

|

|

|

Recommended operator panel | |

| Desktop or laptop |

| At least Pentium III |

| ≥ 800 MHz |

| 1 x Ethernet |

| Windows ME, 2000 or XP |

|

|

The compact analytical module contains all the functional components of a chromatograph. The MicroSAM works with:

The MicroSAM has a two-stage injection system. Using a micro injection valve, a defined quantity of sample is first brought up to the carrier gas pressure. This eliminates the pressure-dependent error in the dosing quantity present with conventional systems. In the second stage, the sample is transferred to the column by a valveless micro injection system (live dosing). The result is an "active" injection.

The injection volume can be varied time-controlled, and exactly matched to the column requirements.

Because of the high dead volume of conventional valves, only the valveless version can be considered for a miniaturized system. In this case, the generation of differences in flow using several electronic pressure regulators at appropriate positions of the column setup causes a change in the flow directions. (The system operates according to the Wheatstone principle, but pneumatically.) The functions "Cut" and "Backflushing" can then be implemented free of dead volume.

The column system consists of two or three capillary columns connected in sequence. Micro TCDs or micro live circuits are installed in sequence ("inline") upstream and downstream of the individual columns. Three electronic pressure regulators supply the columns with carrier gas and carry out the switching functions (injection, backflushing and cut).

By using narrow-bore capillary columns, the separation at high resolution is carried out within a much shorter time, approx. factor 2 to 3 compared to standard capillary columns.

A high pressure stability together with rapid changing rates in the hPa range are required for precise and fast switching. This is achieved in the electronic pressure regulators by means of a piezo actuator.

The micro TCDs (based on silicon wafer technology) work on the principle of continuous measurement of the different thermal conductivities of the carrier gas and the components to be measured.

The measurement can be carried out without falsification by avoiding catalytic effects on the heating wires and maintaining a constant flow velocity. This permits consistent in-line detection, i.e. without qualitative or quantitative losses of substances.

The standardized application modules all contain live injection and live switching. The modules D01 to D03 have four detectors and three separating columns, D04 to D08, D10 and D11 have three detectors and two separating columns, and D09 has three detectors and three separating columns.

The application modules are suitable for separation of the components described below.

Detector | Column 1 | Detector | Column 2 | Detector | Circuit | Column 3 | Detector | |

|---|---|---|---|---|---|---|---|---|

D01 | ||||||||

Injection | TCD | Sil5 C3, C4, C5, C6+ | TCD | PoraPLOT/Porabond Q CO2, C2, H2O | TCD | Live | Molecular filter H2, (Ar+O2), N2, C1, CO | TCD |

D02 | ||||||||

Injection | TCD | Sil5 C5+ | TCD | SilicaPLOT C2, C3, C4 (saturated, unsaturated), C5+ | TCD | Live | Molecular filter H2, (Ar+O2), N2, C1, CO | TCD |

D03 | ||||||||

Injection | TCD | Sil5 C5+ | TCD | Wax Volatile pole components such as alcohol, ether, ketones, aldehydes, C7+ | TCD | Live | ALOX C1, C2, C3, C4 (saturated, unsaturated) | TCD |

D09 | ||||||||

Injection | - | Sil5 Non-polar aromatic and aliphatic hydrocarbons | TCD | Sil5 Non-polar aromatic and aliphatic hydrocarbons | TCD | Live | Porabond Q All components except molecular filter components | TCD |

Application modules D01 to D03 and D09

Detector | Column 1 | Detector | Circuit | Column 2 | Detector | |

|---|---|---|---|---|---|---|

D04 | ||||||

Injection | TCD | Wax Volatile pole components such as alcohol, ether, ketones, aldehydes, C7+ | TCD | Live | SilicaPLOT C2, C3, C4, C5, C6 (saturated, unsaturated) | TCD |

D05 | ||||||

Injection | TCD | Wax Polar aromatic and aliphatic hydrocarbons | TCD | Live | Wax Polar aromatic and aliphatic hydrocarbons | TCD |

D06 | ||||||

Injection | TCD | Sil5 Non-polar aromatic and aliphatic hydrocarbons | TCD | Live | Sil5 Non-polar aromatic and aliphatic hydrocarbons | TCD |

D07 | ||||||

Injection | TCD | Wax Polar aromatic and aliphatic hydrocarbons | TCD | Live | Sil5 Non-polar aromatic and aliphatic hydrocarbons | TCD |

D08 | ||||||

Injection | TCD | Porabond Q All components except molecular filter components | TCD | Live | Molecular filter H2, (Ar+O2), N2, C1, CO | TCD |

D10 | ||||||

Injection | TCD | Sil5 Non-polar aromatic and aliphatic hydrocarbons | TCD | Live | Wax Polar aromatic and aliphatic hydrocarbons | TCD |

D11 | ||||||

Injection | TCD | RTX-5+ Non-polar aromatic and aliphatic hydrocarbons and medium-pole components such as chlorosilane | TCD | Live | SilicaPLOT C2, C3, C4, C5, C6 (saturated, unsaturated) | TCD |

Application modules D04 to D08, D10 and D11

Various solution concepts are available:

MicroSam, dimensions in mm

For easy mounting, incl. support for 8 gas connections consisting of:

The bracket is stipulated in the manual.

Exception

The bracket is not required if the MicroSAM is fitted in a protective casing approved by Siemens. In this case, however, shipping of the unit is only permissible in this protective casing.

For up to 4 sample streams (including calibration stream); e.g. 3 sample streams + 1 calibration stream; controlled by 4 internal digital outputs (relay contact 0.4 A / 24 V DC)

This position contains a basic unit prepared for integration of the analyzer modules.

Individual customers standard.

The workstation operating software can only be ordered together with MicroSAM. Workstation operating software is required for each gas chromatograph network.

Comprehensive and specific development of the method is required for the tasks.

The measured components and switching functions are entered completely using a customer sample (or a specially selected calibration gas). Proof of repeatability is carried out in accordance with the customer specification.

If a natural gas analyzer for calculation of the calorific value is ordered, the evaluation parameters are specifically optimized for the natural gas analysis.

The required BASIC programs (H0X) are installed in the gas chromatograph.

The retention time window C6+ is set to the measured components n-C6 to C9.

The scope of delivery is checked and the documentation and operation of the device explained in detail during the factory acceptance.

This also comprises presentation of the analytical solution including communication, chromatograms, piping plan and gas path plan. If present, inspection of the sample preparation and discussion of the documentation are carried out.

Please supplement the order for J02 to J04 by the desired option from E0x.

Only experienced MicroSAM users should consider the option for starting up the MicroSAM in the context of remote acceptance, e.g. using a telephone conference (on request).

Proof of repeatability over a period of 2 h is included as standard. Longer proof of repeatability for the unit can be ordered using the supplements E02 to E04.

Implementation and testing of a Modbus table for Modbus communication (RS 232 / RS 485 RTU).

The MicroSAM basic unit provides four digital inputs and outputs. If more interfaces are required, these are provided by the I/O Extender. It should be noted, however, that the I/O Extender requires two device-internal digital inputs and outputs. The I/O Extender solution can generate up to 12 additional analog outputs for the chromatograph (further inputs and outputs on request). The latest generation of NESSI components for sample preparation can also be controlled. The max. cable length between MicroSAM (including master cable) and I/O-Extender must not exceed 20 m. A 24 V DC power supply is required for the I/O Extender. This must be provided separately, but can also be covered by the power supply of the MicroSAM.

Note:

If the delivery is to include a protective casing from the Set CV range, please refer to this category in Catalog PA 01. There you can find more information on the I/O Extender and its specification within this total solution.

This position includes:

The delivery package of the I/O Extender solution for Class I Div 2 contains adapters (female thread 1", 3/4", 1/2" for fitting of conduits) which are suitable for cable glands in accordance with this hazardous area.

This position includes:

The delivery package of the I/O Extender solution for Class I Div 2 contains adapters (female thread 1", 3/4", 1/2" for fitting of conduits) which are suitable for cable glands in accordance with this hazardous area.

The BASIC programs are either preset ex-works or can be created and modified by the customer.

The MicroSAM BASIC Editor allows individual programming of calculations and functions by the user.

The following physical variables must be calculated in accordance with the standard: calorific value, heating value, Wobbe index, density, relative density.

The calorific value is calculated as standard in MJ/m3 on a molar basis referred to the reference temperature 25 / 0 °C (combustion/metering temperature). Calculation on the basis of other reference variables or tables (in accordance with the standard) requires unambiguous specification by the customer.

The BASIC program is preset ex works; a customer modification is only possible with the supplement H01.

The following physical variables must be calculated in accordance with the standard: calorific value, relative density and compressibility factor.

The calorific value is calculated as standard in BTU/ft3 (S) referred to the reference temperature 60 °F. Calculation on the basis of other reference variables or tables (in accordance with the standard) requires unambiguous specification by the customer.

The BASIC program is preset ex works; a customer modification is only possible with the supplement H01.

The following physical variables must be calculated in accordance with the standard: calorific value, heating value, Wobbe index, relative density.

These parameters are calculated based on the physical properties of the pure components. As a special feature, the methane concentration is defined as the residual value in this operating mode.

The BASIC program is preset ex works; a customer modification is only possible with the supplement H01.

An unambiguous description of the task is required in order to guarantee correct functioning of the program.

The BASIC program is preset ex works; a customer modification is only possible with the supplement H01.

The supplement H03 is only possible together with C0X.

Calibration gas I in vol.% | Calibration gas II in vol.% | Calibration gas III in vol.% | |

|---|---|---|---|

1.2-butadiene | – | – | 0.1 |

1.3-butadiene | – | – | 0.1 |

1-butene | – | – | 0.1 |

2.2 dimethylpropane | 0.3 | 0.3 | – |

cis-2-butene | – | – | 0.1 |

Cyclopropane | – | – | 0.1 |

Ethane | 4 | 4 | 0.1 |

Ethene | – | – | 0.1 |

Ethine | – | – | 0.1 |

Ethyl acetylene | – | – | 0.1 |

Helium | – | – | Remainder |

Isobutane | 0.5 | 0.5 | 0.1 |

Isopentane | 0.3 | 0.3 | – |

Isopentane | – | – | 0.1 |

Carbon dioxide | 2 | 2 | – |

Methane | Approx. 85 | Approx. 84.5 | 0.1 |

Methyl acetylene | – | – | 0.1 |

n-butane | 0.5 | 0.5 | 0.1 |

n-heptane | 0.05 | 0.05 | – |

n-hexane | 0.05 | 0.05 | 0.1 |

n-pentane | 0.3 | 0.3 | 0.1 |

Propadiene | – | – | 0.1 |

Propane | 2 | 2 | 0.1 |

Propene | – | – | 0.1 |

Oxygen | 0.1 | – | – |

Nitrogen | 5 | 5 | – |

trans-2-butene | – | – | 0.1 |

Vinyl acetylene | – | – | 0.1 |

Hydrogen | – | 0.5 | – |

Standard calibration gases for system test and run-out

Box with I/O Extender

| Код | Заказной номер | Заказать |

|---|---|---|

| 117255 | 7KQ3101-... | Заказать |