The US Food & Drug Administration (FDA) recognized that the introduction of efficient production procedures in the pharmaceutical industry was hampered in the past by legal obstacles. To simplify and accelerate the development and introduction of products, therefore, it drew up a specification for process analytical technology (PAT) and adopted this in its final version in September 2004.

PAT is a system with which product development and production processes can be designed, analyzed and controlled on the basis of real-time measurements of critical quality and performance attributes in such as way that the achievement of the quality required for the end product can be guaranteed. According to this system, the production takes place in a strictly controlled process that is oriented toward producing products of perfect quality.

The real-time tracking of the parameters relevant for product quality also aids better understanding and management of the overall process as well as avoiding or considerably reducing the scope of final inspections. The preparation of samples for quality control at the end of the process (which can sometimes be extremely time-consuming) or for follow-up checks can thus be omitted.

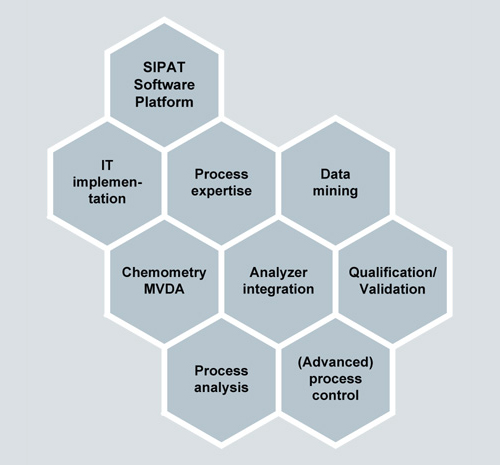

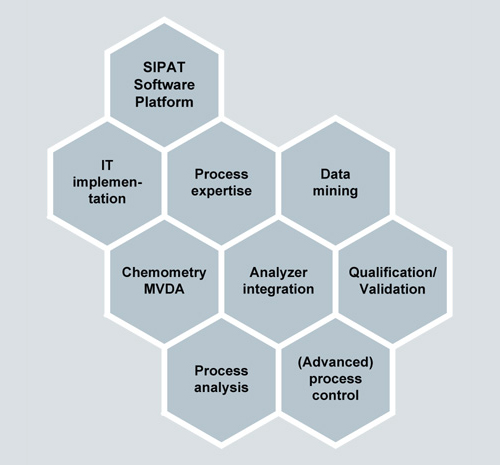

With SIMATIC SIPAT, Siemens has a powerful software platform for PAT implementation in product development and production processes (for details, see Chapter "Industry Applications", Section "Process Analytical Technology").

To accompany this, Siemens offers the Premium Service SIMATIC SIPAT Consulting particularly for customers from the pharmaceutical industry and related industries. This provides additional consultation services as well as experimental investigations for the PAT integration, providing valuable support in the development, pilot project and production phases:

- Project management

- Evaluation of suitable production processes

- Evaluation of suitable analytical processes

- Process optimization

- Risk analysis

- Design of Experiment

- Multivariate data analysis

- Personnel training

- Fast capture of information about the key parameters of the manufacturing process

- Reproducible process permit consistently high product quality

- Qualitative early indication on the basis of an improved understanding of the process

- Sensitive processes can be controlled/regulated around the clock

- Reduction or elimination of release tests for intermediate and end products

- Future legal requirements with regard to risk-based validation can already be implemented today

- Shortening of process cycle times and improvement of total performance of the process

- Maximization of product yield

- Saving of raw and auxiliary materials

- Minimization of scale-up risks

The Premium Service SIMATIC SIPAT Consulting is split into three complementary modules that can be ordered individually:

Module 1:

Determination of PAT potential through analysis by experts

- One-day workshop for analyzing the customer's production processes

- Participants: Siemens experts and representatives of the client with profound knowledge of the process

- Pre-definition of workshop details between client and contractor, e.g. discussion of the client's production processes and possible real-time process analysis systems, if necessary including tour of the existing production plant

- Assessment of the benefit of the PAT implementation on the basis of criteria such as:

- Avoidable incorrect batches

- Reducible release tests

- Effect on process cycle times

- Necessary investment

- Result: Workshop documentation with qualitative evaluation of the PAT potential, and specific recommendations for further actions

Module 2:

Preparation of a feasibility study

- Feasibility study to verify and narrow down the potential identified in Module 1 (processing time up to two weeks):

- Detailed consideration of as many as 10 recorded processing steps

- Closer examination of potential process analysis systems with regard to suitability and integration into the process

- Participants: Siemens experts and representatives of the client

- Basic material:

- Customer information

- Values gained from own experience

- Literature about process analysis systems

- Manufacturers' information process analysis systems

- Results of an expert analysis (Module 1)

- Inclusive services:

- Evaluation of existing production processes, process parameters and process controls: Apparatus, process knowledge, process control, manageability and performance capability of the processes, specifications of the raw materials

- Evaluation of product quality Identification of the known quality parameters, their limits and analytical test methods

- Correlation of quality and process parameters, evaluation of known or suspected causes of process failures (batches outside the specification)

- Determination of processes with potential for improvement through in-process control

- Characterization of the tasks for in-process control

- Evaluation of known/potential online or inline analysis methods and analyzers for the in-process controls; assessment on the basis of data from corresponding offline and online laboratory methods

- Evaluation of potential process interfaces or potential equipment for automatic sampling

- Extra services (separate charge):

- Siemens examines a selection of in-house process analysis systems for suitability for the real-time process analysis

- Execution in own laboratories with samples of varying quality

- Invoicing of analysis performed by Siemens on pro rata basis

- Result: Documentation of the feasibility study with concluding evaluation of the PAT potential and specific recommendations for further actions

Module 3:

Implementation of the prepared feasibility study

- Implementation of knowledge gained in Modules 1 and 2 in a specific project for supporting the PAT implementation

- Content is the subject of an individual agreement between client and contractor

- Typical service content:

- Risk analysis

- Support in selecting and installing a process analysis system

- Support in drawing up the "Design of Experiment" (DoE) and execution of the experiments for structured investigation of the "Design Space"

- Data analysis, e.g. multivariate (MVDA)

- Interpretation of the results

- Process optimization on the basis of the understanding gained of the process and, if necessary, modification of the "design space"

- Basis for the individual agreement is a project-specific quotation provided by Siemens as the contractor

- Inquiries for production of a quotation should be directed to the address specified under "Further information"

Note:

The modules of the Premium Service SIMATIC SIPAT do not include any traveling expenses. Traveling expenses from the Hoechst Industrial Estate, Frankfurt am Main, Germany, will be invoiced separately.

Siemens AG

Industry Sector

Industry Automation Division

Industrial Automation Systems

Industriepark Höchst, Gebäude B 598

65926 Frankfurt am Main

Tel.: +49 69 797 84500

E-mail: team-ec.industry@siemens.com

You can find additional information on the Internet at:

http://www.siemens.de/ec