ULTRAMAT/OXYMAT 6, 19" rack unit | |

General information | |

Operating position | Front wall, vertical |

Conformity | CE mark in accordance with EN 50081-1, EN 50082-2 |

Design, enclosure | |

Weight | Approx. 21 kg |

Degree of protection | IP20 according to EN 60529 |

Electrical characteristics | |

EMC (Electromagnetic Compatibility) | In accordance with standard requirements of NAMUR NE21 (08/98) |

Electrical safety | According to EN 61010-1, overvoltage category III |

Power supply | 100 ... 120 V AC (nominal range of use 90 ... 132 V), 48 ... 63 Hz or |

Power consumption | Approx. 70 VA |

Fuse values | 120 ... 120 V: F1/F2 = T 1.6 A |

Electrical inputs and outputs (per channel) | |

Analog output | 0/2/4 ... 20 mA, isolated; max. load 750 Ω |

Relay outputs | 6, with changeover contacts, freely parameterizable, e.g. for measuring range identification; load: 24 V AC/DC/1 A, isolated, non-sparking |

Analog inputs | 2, dimensioned for 0/2/4 … 20 mA for external pressure sensor and correction of influence of accompanying gas (correction of cross-interference) |

Binary inputs | 6, designed for 24 V, isolated, freely parameterizable, e.g. for measuring range switchover |

Serial interface | RS 485 |

Options | AUTOCAL function each with 8 additional binary inputs and relay outputs, also with PROFIBUS PA or PROFIBUS DP |

Climatic conditions | |

Permissible ambient temperature | -30 ... +70 °C during storage and transportation, 5 … 45 °C during operation |

Permissible humidity | < 90% relative humidity, during storage and transportation (dew point must not be undershot) |

Technical data, ULTRAMAT channel | |

Measuring ranges | 4, internally and externally switchable; autoranging is also possible |

Smallest possible measuring range | Dependent on the application, e.g. |

Largest possible measuring range | Dependent on the application |

Measuring ranges with suppressed zero point | Any zero point within 0 ... 100 vol.% can be implemented; smallest possible span 20 % |

Characteristic | Linearized |

Influence of interfering gases must be considered separately | |

Gas inlet conditions | |

Permissible sample gas pressure | |

| 700 ... 1 500 hPa (absolute) |

| 700 ... 1 300 hPa (absolute) |

Sample gas flow | 18 ... 90 l/h (0.3 ... 1.5 l/min) |

Sample gas temperature | Min. 0 to max. 50 °C, but above the dew point |

Sample gas humidity | < 90% (relative humidity), or dependent on measuring task, non-condensing |

Dynamic response | |

Warm-up period | At room temperature < 30 min (the technical specification will be met after 2 hours) |

Delayed display (T90-time) | Dependent on length of analyzer chamber, sample gas line and parameterizable damping |

Damping (electrical time constant) | 0 ... 100 s, parameterizable |

Dead time (purging time of the gas path in the unit at 1 l/min) | Approx. 0.5 ... 5 s, depending on version |

Time for device-internal signal processing | < 1 s |

Pressure correction range | |

Pressure sensor | |

| 700 ... 1 200 hPa absolute |

| 700 ... 1 500 hPa absolute |

Measuring response (relating to sample gas pressure 1 013 hPa absolute, 0.5 l/min sample gas flow and 25 °C ambient temperature) | |

Output signal fluctuation | < ± 1% of the smallest possible measuring range according to rating plate |

Zero point drift | <± 1% of the current measuring range/week |

Measured-value drift | <± 1% of the current measuring range/week |

Repeatability | ≤ 1% of the current measuring range |

Detection limit | 1 % of the smallest possible measuring range |

Linearity error | < 0.5% of the full-scale value |

Influencing variables (relating to sample gas pressure 1 013 hPa absolute, 0.5 l/min sample gas flow and 25 °C ambient temperature) | |

Ambient temperature | < 1% of current measuring range/10 K (with constant receiver cell temperature) |

Sample gas pressure |

|

Sample gas flow | Negligible |

Power supply | < 0.1% of the current measuring range with rated voltage ± 10% |

Environmental conditions | Application-specific measuring influences possible if ambient air contains measured component or cross interference-sensitive gases |

Technical data, OXYMAT channel | |

Measuring ranges | 4, internally and externally switchable; automatic measuring range switchover also possible |

Smallest possible span (relating to sample gas pressure 1 000 hPa absolute, 0.5 l/min sample gas flow and 25 °C ambient temperature) | 0.5 vol.%, 2 vol.% or 5 vol.% O2 |

Largest possible measuring range | 100 vol. % O2 |

Measuring ranges with suppressed zero point | Any zero point within 0 ... 100 vol.% can be implemented, provided that a suitable reference gas is used |

Gas inlet conditions | |

Permissible sample gas pressure | |

| 500 ... 3 000 hPa absolute |

| |

| 500 ... 1 500 hPa absolute |

| 500 ... 1 300 hPa absolute |

Sample gas flow | 18 ... 60 l/h (0.3 ... 1 l/min) |

Sample gas temperature | 0 ... 50 ºC |

Sample gas humidity | < 90% RH (relative humidity) |

Reference gas pressure (high-pressure version) | 2 000 ... 4 000 hPa above sample gas pressure, but max. 5 000 hPa |

Reference gas pressure (low-pressure version) | Min. 100 hPa above sample gas pressure |

Dynamic response | |

Warm-up period | At room temperature < 30 min (the technical specification will be met after 2 hours) |

Delayed display (T90 time) | Min. 1.5 ... 3.5 s, depending on version |

Damping (electrical time constant) | 0 ... 100 s, parameterizable |

Dead time (purging time of the gas path in the unit at 1 l/min) | Approx. 0.5 ... 2.5 s, depending on version |

Time for device-internal signal processing | < 1 s |

Pressure correction range | |

Pressure sensor | |

| 500 ... 2 000 hPa absolute |

| 500 ... 3 000 hPa absolute |

Measuring response (relating to sample gas pressure 1 013 hPa absolute, 0.5 l/min sample gas flow and 25 °C ambient temperature) | |

Output signal fluctuation | < 0.75% of the smallest possible measuring range according to rating plate, with electronic damping constant of 1 s (corresponds to ± 0.25% at 2σ) |

Zero point drift | < 0.5%/month of the smallest possible measuring span according to rating plate |

Measured-value drift | ≤ 0.5%/month of the current measuring range |

Repeatability | ≤ 1%/month of the current measuring range |

Detection limit | 1% of the current measuring range |

Linearity error | 1% of the current measuring range |

Influencing variables (relating to sample gas pressure 1 013 hPa absolute, 0.5 l/min sample gas flow and 25 °C ambient temperature) | |

Ambient temperature |

|

Sample gas pressure (with air (100 hPa) as reference gas, correction of the atmospheric pressure fluctuations is only possible if the sample gas can vent to ambient air) |

|

Accompanying gases | Deviation from zero point corresponding to paramagnetic or diamagnetic deviation of accompanying gas |

Sample gas flow | < 1% of the smallest possible span according to rating plate with a change in flow of 0.1 l/min within the permissible flow range |

Power supply | < 0.1 % of the current measuring range with rated voltage ± 10% |

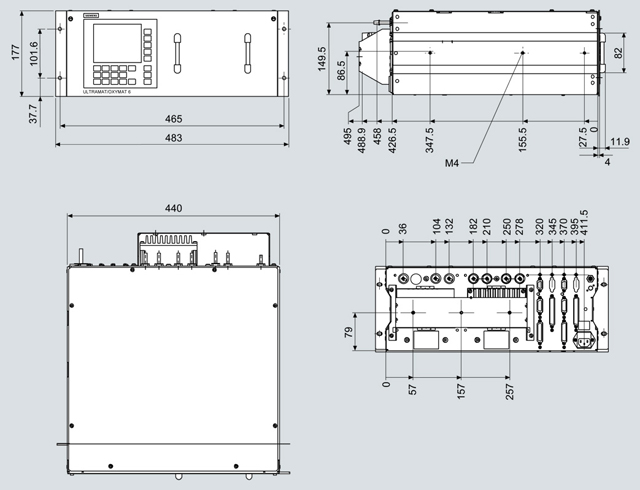

ULTRAMAT/OXYMAT 6, 19“ unit, dimensions in mm

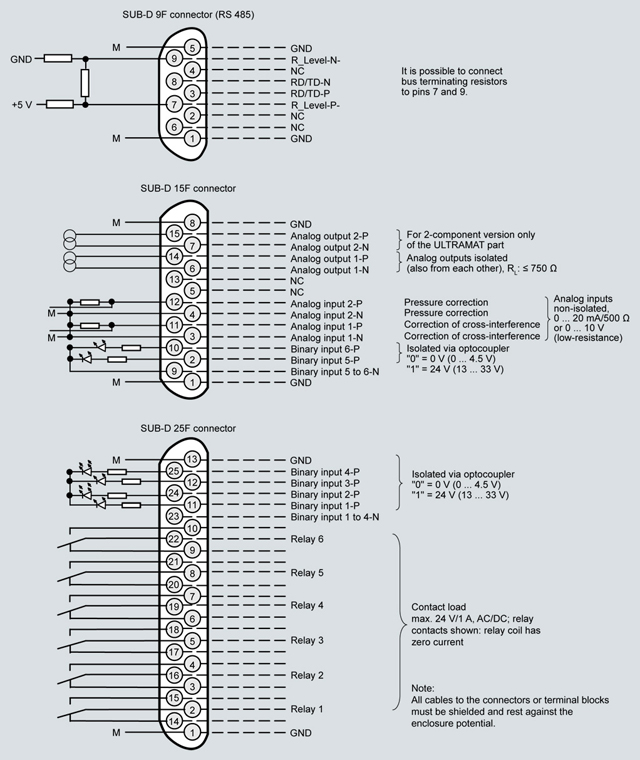

ULTRAMAT/OXYMAT 6, 19“ unit, pin assignment

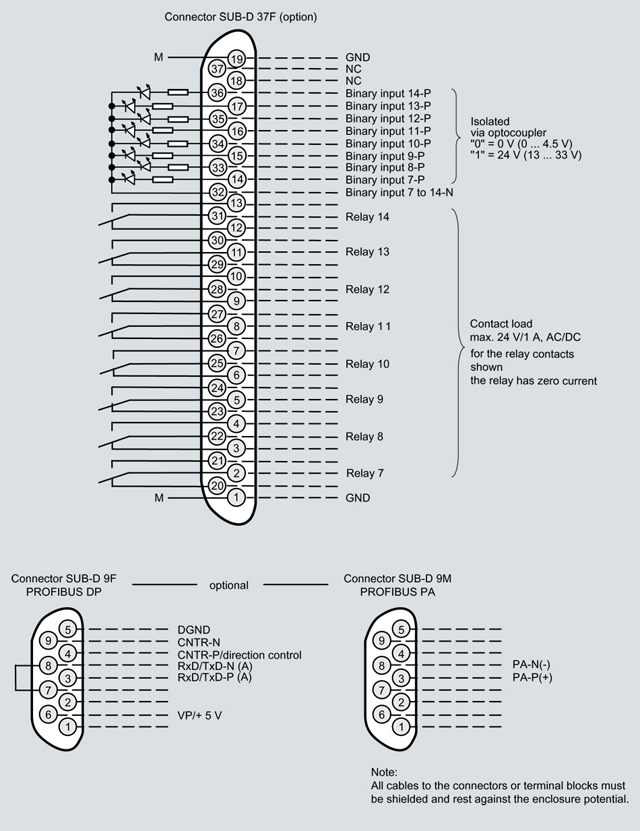

ULTRAMAT/OXYMAT 6, 19“ unit, pin assignment of AUTOCAL board and PROFIBUS connectors

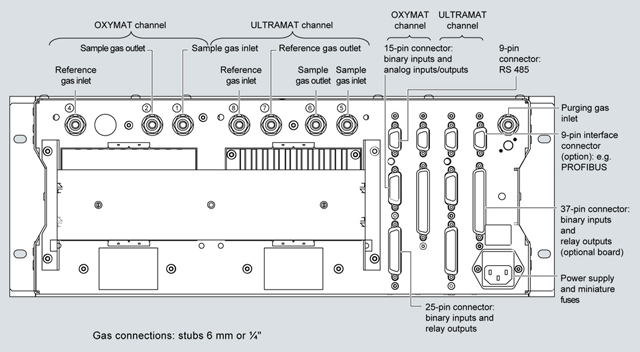

ULTRAMAT/OXYMAT 6, 19“ unit, gas and electrical connections

| Код | Заказной номер | Описание | Вес (кг) | Заказать |

|---|---|---|---|---|

| 117339 | 7MB2023-.....-.... | анализатор ultramat/oxymat 6 исполнение 19" для монтажа в шкаф | 21 | Заказать |

| 70843 | 7MB2024-.....-.... | анализатор ultramat 6 для измерения компонентов в инфрокрасном диапазоне, шкафное исполнение | 21 | Заказать |

| 77977 | A5E00057307 | autocal board with 8 binary- inputs/outputs and profibus pa | 0.5 | Заказать |

| 124413 | A5E00057312 | autocal board with mit 8 binary inputs and 8 binary outputs and profibus dp | 0.5 | Заказать |

| 78169 | A5E00852382 | usb-rs485 converter | 1 | Заказать |

| 124619 | A5E00852383 | rs 485 / ethernet-converter | 1 | Заказать |

| 125988 | C79000-G5200-C143 | manual ultramat 6 / oxymat 6 | 0.42 | Заказать |

| 79601 | C79000-G5272-C143 | manual (italian) ultramat 6e / oxymat 6e | 0.42 | Заказать |

| 79602 | C79000-G5276-C143 | manual (english) ultramat 6 / oxymat 6 | 0.8 | Заказать |

| 79604 | C79000-G5277-C143 | manual (french) ultramat6 / oxymat6 | 0.335 | Заказать |

| 79606 | C79000-G5278-C143 | manual (spanish) ultramat6 / oxymat6 | 0.41 | Заказать |

| 79692 | C79451-A3480-D33 | retrofit kit serial interface for automotiv (ak)for ultramat 6e 2p and ultramat/oxymat 6e | 0.25 | Заказать |

| 126071 | C79451-A3480-D511 | additional electronics modul | 0.243 | Заказать |

| 126081 | C79451-Z1589-U1 | interface converter rs 485 / rs 232 (retrofit set) | 0.716 | Заказать |