Diaphragm seals of sandwich design

Diaphragm seals of sandwich design | |

| PN 16 ... PN 100 |

| PN 16 ... PN 100 |

| PN 16 ... PN 100 |

| PN 16 ... PN 100 |

| Class 150 ... class 2500 |

| Class 150 ... class 2500 |

| Class 150 ... class 2500 |

| Class 150 ... class 2500 |

Sealing face | |

| To EN 1092‑1, form B1 or ASME B16.5 RF 125 … 250 AA |

| To EN 1092‑1, form B2 or ASME B16.5 RFSF |

Materials | |

| Stainless steel, Mat. No. 1.4404/316L |

| Stainless steel, Mat. No. 1.4404/316L |

| |

| |

| |

| |

Monel 400, mat. No. 2.4360 | |

Hastelloy C276, mat. No. 2.4819 | |

Hastelloy C4, mat. No. 2.4610 | |

Tantalum | |

| Stainless steel 1.4571/316Ti |

| Spiral hose made of stainless steel, mat. No. 1.4301/316 |

Sealing material in the process flanges | |

| Copper |

| Viton |

Maximum pressure | See above and the technical data of the pressure transmitters |

Tube length | Without tube as standard (tube available on request) |

Capillary | |

| Max. 10 m (32.8 ft), longer lengths on request |

| Max. 2 mm (0.079 inch) |

| 150 mm (5.9 inch) |

Filling liquid | Silicone oil M5 |

Silicone oil M50 | |

High-temperature oil | |

Halocarbon oil (for measuring O2) | |

Food oil (FDA-listed) | |

Glycerin/water (not suitable for use in low-pressure range) | |

Permissible ambient temperature | Dependent on the pressure transmitter and the filling liquid of the remote seal More information can be found in the technical specifications of the pressure transmitters and in the section "Technical data of filling liquid" in the introduction to the remote seals |

Weight | Approx. 4 kg (8.82 lb) |

Certificates and approvals | |

Classification according to pressure equipment directive (PED 97/23/EC) | For gases of fluid group 1 and liquids of fluid group 1; complies with requirements of article 3, paragraph 3 (sound engineering practice) |

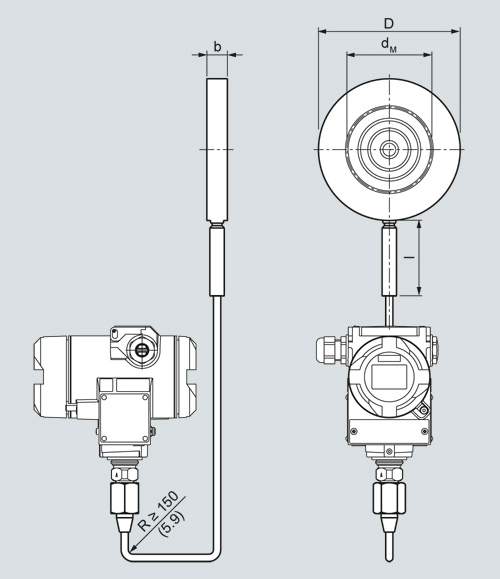

Diaphragm seals of sandwich design with flexible capillary for connection to SITRANS P pressure transmitters for pressure, dimensions in mm (inch)

Nominal diameter | Nominal pressure | L | D | dM | l |

|---|---|---|---|---|---|

mm (inch) | mm (inch) | mm (inch) | mm (inch) | ||

DN 50 | PN 16 ... PN 100 | 20 | 102 | 59 | 100 |

DN 80 | 20 | 138 | 89 | 100 | |

DN 100 | 20 | 158 | 89 | 100 | |

DN 125 | 22 | 188 | 124 | 100 |

Nominal diameter | Nominal pressure | L | D | dM | I |

|---|---|---|---|---|---|

lb/sq.in. | mm (inch) | mm (inch) | mm (inch) | mm (inch) | |

(inch) | (inch) | (inch) | (inch) | ||

2 inch | 150 … 2500 | 20 | 100 | 59 | 100 |

(0.79) | (3.94) | (2.32) | (3.94) | ||

3 inch | 20 | 134 | 89 | 100 | |

(0.79) | (5.28) | (2.32) | (3.94) | ||

4 inch | 20 | 158 | 89 | 100 | |

(0.79) | (6.22) | (2.32) | (3.94) | ||

5 inch | 22 | 186 | 124 | 100 | |

(0.87) | (7.32) | (4.88) | (3.94) |

d: Inside diameter of gasket according to EN 1092-1 / ASME B16.5

dM: Effective diaphragm diameter

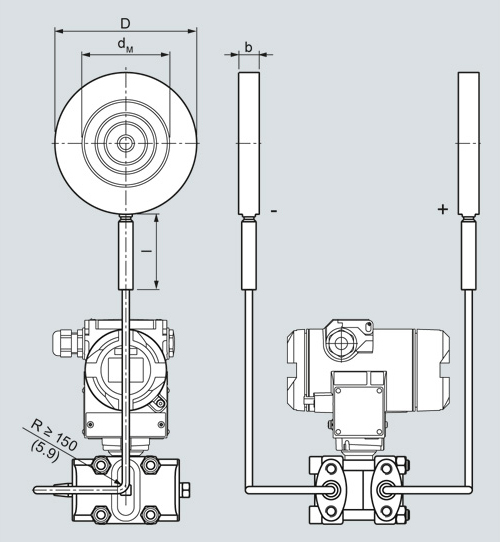

Diaphragm seals of sandwich design (without flange) with flexible capillary for connection to SITRANS P pressure transmitters for absolute pressure or differential pressure and flow, dimensions in mm (inch)

Nominal diameter | Nominal pressure | L | D | dM | l |

|---|---|---|---|---|---|

mm (inch) | mm (inch) | mm (inch) | mm (inch) | ||

DN 50 | PN 16 ... PN 100 | 20 | 102 | 59 | 100 |

DN 80 | 20 | 138 | 89 | 100 | |

DN 100 | 20 | 158 | 89 | 100 | |

DN 125 | 22 | 188 | 124 | 100 |

Nominal diameter | Nominal pressure | L | D | dM | I |

|---|---|---|---|---|---|

lb/sq.in. | mm (inch) | mm (inch) | mm (inch) | mm (inch) | |

(inch) | (inch) | (inch) | (inch) | ||

2 inch | 150 … 2500 | 20 | 100 | 59 | 100 |

(0.79) | (3.94) | (2.32) | (3.94) | ||

3 inch | 20 | 134 | 89 | 100 | |

(0.79) | (5.28) | (2.32) | (3.94) | ||

4 inch | 20 | 158 | 89 | 100 | |

(0.79) | (6.22) | (2.32) | (3.94) | ||

5 inch | 22 | 186 | 124 | 100 | |

(0.87) | (7.32) | (4.88) | (3.94) |

d: Inside diameter of gasket according to EN 1092-1 / ASME B16.5

dM: Effective diaphragm diameter

| Код | Заказной номер | Описание | Вес (кг) | Заказать |

|---|---|---|---|---|

| 71455 | 7MF4900-.....-.. | разделительная мембрана, тип 7mf4900 | 2 | Заказать |

| 71456 | 7MF4901-.....-.. | разделительная мембрана, тип 7mf4901 | 2 | Заказать |

| 117959 | 7MF4903-1....-.B | разделительная мембрана,ячеечного исполнения (2 штуки) для датчика дифдавления sitrans p | 5 | Заказать |