SITRANS P MPS pressure transmitters are submersible sensors for hydrostatic level measurements.

The SITRANS P MPS pressure transmitters are available for various measuring ranges and with explosion protection as an option.

A junction box and a cable hanger are available as accessories for simple installation.

SITRANS P MPS pressure transmitters are used in the following branches for example:

SITRANS P MPS pressure measurement transmitter (submersible sensor) | |

Mode of operation | |

Measuring principle | piezo-resistive |

Input | |

Measured variable | Hydrostatic level |

Measuring range | Maximum operating pressure |

|

|

|

|

|

|

|

|

|

|

|

|

Output | |

Output signal | 4 ... 20 mA |

Measuring accuracy | According to IEC 60770-1 |

Error in measurement at limit setting incl. hysteresis and reproducibility | 0.3% of full-scale value (typical) |

Influence of ambient temperature | |

Zero and span | |

| 0.45 %/10 K of full-scale value |

| 0.3 %/10 K of full-scale value |

Long-term stability | |

Zero and span | |

| 0.25 % of full-scale value/year |

| 0.2 % of full-scale value/year |

Rated conditions | |

Ambient conditions | |

| -10 ... +80 °C (+14 ... +176 °F) |

| -40 ... +100 °C (-40 ... +212 °F) |

Degree of protection to IEC 60529 | IP68 |

Design | |

Weight | |

| ≈ 0.4 kg (≈ 0.88 lb) |

| 0.08 kg/m (≈ 0.054 lb/ft) |

Electrical connection | Cable with 2 conductors with screen and vent pipe, strength cord (max. 300 N (67.44 lbf)) |

Material | |

| Stainless steel, mat. no. 316L/316 Ti |

| Stainless steel, mat. no. 316L/316 Ti |

| Viton |

| Either |

Auxiliary power supply | |

Terminal voltage on pressure transmitter UB | 10 ... 33 V DC |

Certificates and approvals | |

The transmitter is not subject to the pressure equipment directive (PED 97/23/EC) | |

Explosion protection | |

| TÜV 03 ATEX 2004X |

| Ex II 1 G EEx ia IIC T4 |

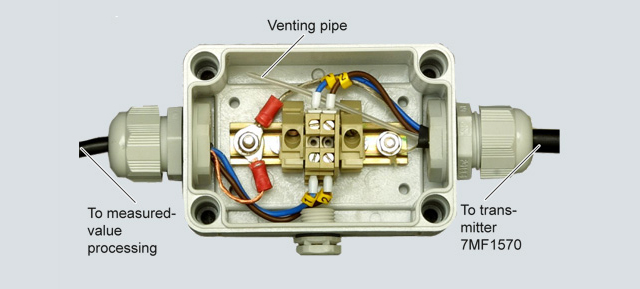

Junction box | |

Application | for connecting the transmitter cable |

Design | |

Weight | 0.2 kg (0.44 lb) |

Electrical connection | 2 x 3-way (28 to 18 AWG) |

Cable entry | 2 x M20x1.5 |

Enclosure material | polycarbonate |

Vent pipe for atmospheric pressure | |

Screw for cable strength cord | |

Rated conditions | |

Degree of protection to IEC 60529 | IP54 |

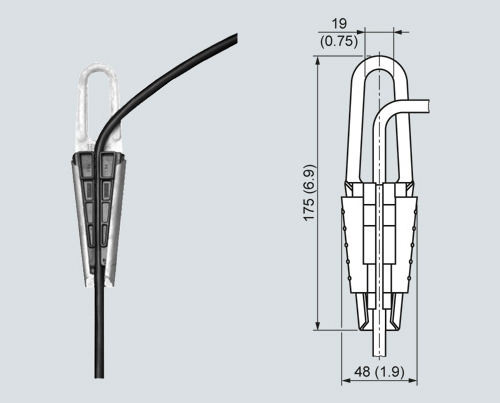

Cable hanger | |

Application | for mounting the transmitter |

Design | |

Weight | 0.16 kg (0.35 lb) |

Material | Galvanized steel, polyamide |

SITRANS P MPS pressure transmitters have a flush-mounted piezo-resistive sensor with stainless steel diaphragm.

These pressure transmitters are equipped with an electronic circuit fitted together with the sensor in a stainless steel housing. The cable also contains a strength cord and vent pipe.

The diaphragm is protected against external influences by a protective cap.

The sensor, electronic circuit and cable are sealed in a common housing of small dimensions.

The pressure transmitter is temperature-compensated for a wide temperature range.

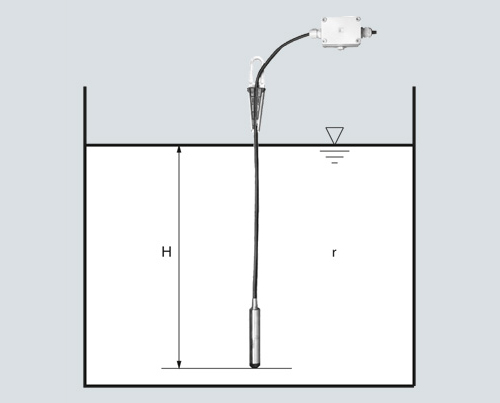

SITRANS P MPS pressure transmitters are for measuring the liquid levels in wells, tanks, channels and dams.

SITRANS P MPS pressure transmitter, mode of operation and wiring diagram

On one side of the sensor, the diaphragm is exposed to the hydrostatic pressure which is proportional to the submersion depth. This pressure is compared with atmospheric pressure. Pressure compensation is carried out using the vent pipe in the connection cable.

The hydrostatic pressure of the liquid column acts on the sensor diaphragm, and transmits the pressure to the piezo-resistive bridge in the sensor.

The output voltage of the sensor is applied to the electronic circuit where it is converted into an output current of 4 to 20 mA.

The cable of the 7MF1570 transmitter must always be connected in the supplied junction box. The junction box has to be installed near the measuring point.

If the medium is anything other than water, it is also necessary to check compatibility with the specified materials of the transmitter.

Junction box 7MF1570-8AA, opened

Measuring point setup, in principle

SITRANS P MPS pressure transmitters, dimensions in mm (inch)

Junction box, dimensions in mm (inch)

Cable hanger, dimensions in mm (inch)

Calculation of the measuring range:

p = ρ x g x H

with:

ρ = density of medium

g = local acceleration due to gravity

H = maximum level

Example:

Medium: Diesel fuel, ρ = 850 kg/m3

Acceleration due to gravity: 9.81 m/s2

Start-of-scale: 0 m

Maximum level: 6.2 m

Cable length: 7 m, FEP cable

Calculation:

p = 850 kg/m3 x 9.81 m/s2 x 6.2 m

p = 51698.7 N/m2

p = 517 mbar

Transmitter to be ordered:

7MF1570-9AA01-Z; H5C + Y01

J1Y: 0 ... 517 mbar